Spirals in Pyrolysis

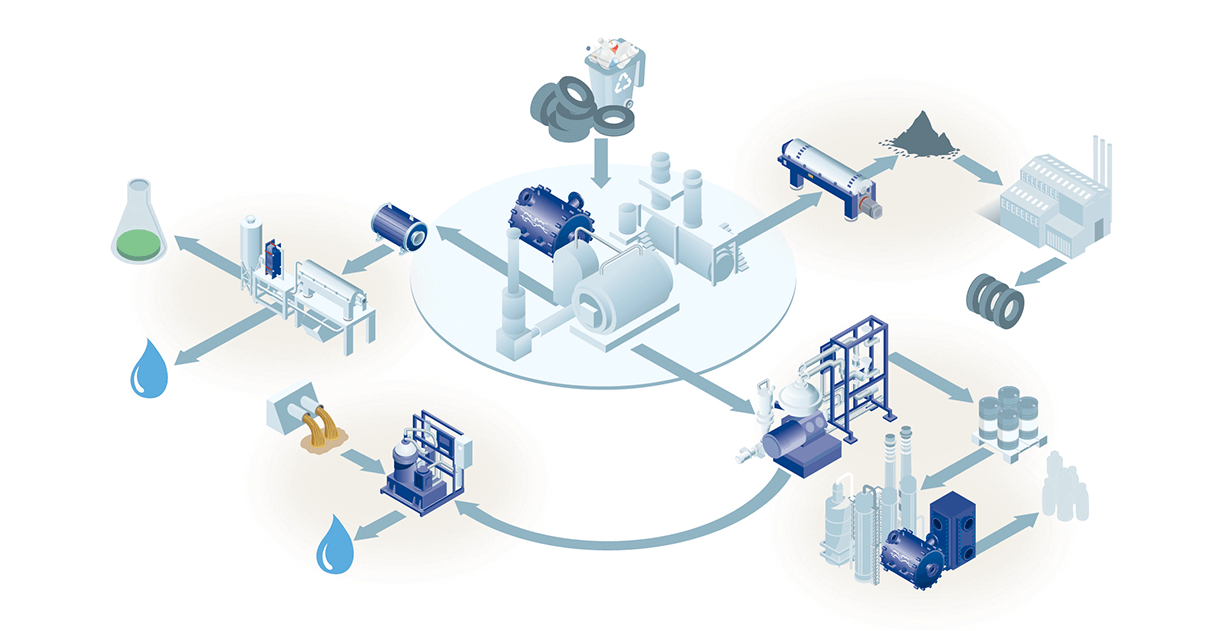

To reach our collective climate goals on time, we need to reuse and recycle as much as we can. Chemical recycling is just one example of how. Pyrolysis is a form of chemical recycling that supports circularity in the harder to abate sectors, as plastic waste and used tyres can be gathered, pyrolyzed to create a synthetic oil, and separated for reuse as a circular feedstock. As you can imagine, this is a messy process that comes with a heavy dose of fouling media and a high likelihood for corrosion.

Alfa Laval was the first company to introduce spiral technology to the world of heat transfer; a design so reliable that it is still number one today. Now, we want to bring this robust technology into the world of plastic recycling. Thanks to its single channel design, this heat exchanger can cope with all kinds of heavy-duty inlet media to make even the stickiest substance easy to process. It uses the high-density deposits that naturally occur to increase velocity and even self-clean, making it the perfect partner for processing heavy oils. With the support of this technology, we hope to open the door to new possibilities in the recycling industry for a cleaner tomorrow.