Solving the palm oil mill effluent (POME) challenge: Convincing results from POMEVap installation in India reinforces Alfa Laval’s sustainability agenda for palm oil mills

Executive summary: Palm oil production is on the increase, which brings with it major economic benefits, but also significant sustainability challenges in terms of the impacts it has on the environment with the generation of methane, water and land use, and waste management. As a member of the Roundtable on Sustainable Palm Oil (RSPO) Alfa Laval is committed to making a major contribution to mitigating against these impacts and has developed an innovative technology called POMEVap that is being used in the treatment of palm oil mill effluent (POME), a by-product of the production process. A case study in India shows how POMEVap makes a substantial difference by ensuring that no methane is generated, minimizing water consumption, recovering additional palm oil and concentrating for reuse, and taking up less space to release land for other purposes.

Date 2567-09-19

Introduction:

Palm oil is widely used as a key ingredient in packaged products – ranging from chocolates, soaps & detergents, cosmetics, and even ice cream -- and accounts for almost 40% of the world’s vegetable oil demand.

The global demand for palm oil production is expected to increase significantly in the near future and such rapid growth will contribute significantly to economies and livelihoods in several countries. However, it will also pose a challenge in terms of achieving sustainable operation of palm oil mills, with demands for higher oil yield but with minimum impact on the environment.

Background and context:

One of the major challenges faced by palm oil millers is the treatment of palm oil mill effluent (POME), which is generated mainly from the palm fruit sterilization and palm oil clarification processes.

POME is a thick, brownish, colloidal mixture of water, oil, and fine suspended solids, and it is characterized by a very high biological oxygen demand (BOD). Owing to the high pollution load (high BOD) in POME, an efficient POME treatment method has become a pre-requisite for the sustainable and successful operation of mills.

Traditional POME treatment involves pumping the wastewater into a system of huge ponds, each the size of a football pitch, where it is treated to the required local discharge standards. This method has several disadvantages: it requires a large area of land; methane is produced and emitted to the atmosphere; and POME contains approximately 1% of the total extracted palm oil, which goes to waste.

Methane is the second most abundant greenhouse gas (GHG), with a global warming potential 28 times higher than carbon dioxide. Methane accounts for about 16% global GHG emissions (IEA, 2024).

Sustainability goals and strategies:

Alfa Laval participates in the Roundtable on Sustainable Palm Oil (RSPO), a global partnership to make palm oil sustainable, and remains committed to the development and implementation of solutions that can reduce the environmental impact of palm oil production.

Environmental impact:

To address these challenges faced by mills, Alfa Laval has developed POMEVap technology to effectively manage the POME issue.

The system uses AlfaFlash evaporation technology to separate the effluent into clear water, recovered palm oil, and a concentrate of nutrient-rich solids, which can be further processed and sold as animal feed.

POMEVap offers several advantages: water consumption is minimized as the condensate can be reused; oil and concentrate can be recovered and sold; less space is needed for wastewater treatment as a typical POMEVap needs just 300 square meters in space; and no methane is produced resulting in next-to complete avoidance of GHG emissions. After concentration, the sludge from the wastewater is dried and used either as feed for livestock or as a technical grade product for agricultural manure.

Best practise:

For one palm oil producer in India, investment in a POMEVap system from Alfa Laval will make it possible for the mill to achieve local environmental standards, facilitating the re-use of condensate in the mill process, which will significantly reduce freshwater consumption, while also dramatically reducing GHG emissions. Overall profitability will also get a boost through the recovery of additional palm oil, which would otherwise have been lost in the POME.

“Efficient treatment of POME was a major concern for this customer because of the effect on the environment and the loss of valuable by-products,” explains Prasanna Upadhyay, CPO Industry Manager, Alfa Laval BU Food Systems.

Following intensive product trials with Alfa Laval’s evaporation test unit during the sales phase, the company was impressed with the performance of the POMEVap solution. The full-scale POMEVap system was installed and successfully commissioned at the plant at the end of 2023, with results meeting the customer’s expectations.

Economic considerations:

With an anticipated payback on investment of just four years thanks to the addition of a decanter step in the POMEVap system to facilitate palm oil recovery, the solution is a win-win.

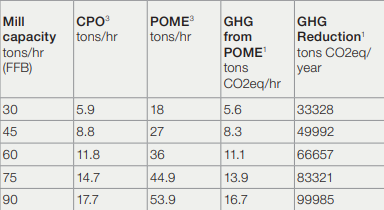

“To give an idea of the oil recovery potential using POMEVap, a mill with a capacity of 45 tons/hour FFB generates approximately 162,000 tons of POME per year,” says Amol Hukkerikar, Senior Global Sales, Alfa Laval BU Food Systems. “The raw POME contains approximately 1% oil and with the POMEVap system, it is possible to recover 50% of the oil, or 810 tonnes per year, which is significant!

“The recovered oil can be returned for oil clarification for further purification, or it can be also used as HVO feedstock allowed under the RED II framework in Europe. To conclude, the POMEVap solution not only assists in generating additional income to the mills but also completely solves the GHG emissions issue associated with the use of ponding system and helps palm oil mills to achieve their sustainability goals.”

Conclusions and call-to-action:

POMEVap is a revolutionary technology from Alfa Laval that significantly reduces the environmental impacts of POME treatment at a time when palm oil production is set to increase massively.

This has the potential to have a major positive global impact, as seen by our customer case study in India. Contact us to find out more about the huge benefits that POMEVap can bring to you and your sustainability drive.

References:

https://www.iea.org/reports/global-methane-tracker-2024

Let’s make the most of it: unlocking the value of wastewater

Based on AlfaFlash Technology, POMEVap efficiently separates effluent into:

Water in the form of process condensate (~300-500 ppm BOD)

Solids in the form of concentrate (sludge with ~40% solids)

Data points from best practice case. The data will vary from case to case in line with the capacity of the processing plant:

Water consumption is minimized as the condensate can be reused

Recovery of 810 tonnes of palm oil per year from wastewater

Methane emissions are reduced to next-to zero