Concentration is key to slashing the carbon footprint of coconut water while keeping water in the local watershed

With the global market for coconut water estimated to be worth USD 2.84 billion in 2024, rising to USD 4.73 billion by 2029, this thirst-quenching drink remains ever-popular with today’s health-conscious consumers.

Date 2567-09-20

For one coconut processor in the Philippines, the challenge has been how to capitalize on this rising consumer demand while also navigating the ongoing global drive for sustainability in food production.

The task for the Coconut producer has been three-fold: reducing the costs and streamlining the logistics involved in transporting large volumes of liquid around the world while also ensuring that water use is optimized during the production process overall.

Every part of a coconut is useful. Its husk becomes coir or rope. Its shell is a source of fuel and charcoal production. The coconut’s testa is used for oil, meat for milk constitute sources of nourishing food. The remaining part can be turned into low-fat desiccated coconut powder, while the coconut water is rich in carbohydrates and electrolytes such as potassium, sodium, and magnesium. Earlier, coconut water was a major challenge to handle and was typically discarded as waste, still many desiccated coconut manufacturers are not aware of the opportunity.

Until recent years, only the water from green coconuts reached the market as a fresh product. The water from mature coconuts was thrown away as a by-product in the production of nata d coco and cake, and it was used to produce desiccated coconut destined for the bakery and confectionary industries. In the mid-2000s, however, consumer demand led coconut processing companies, including the one in question, to reassess the value of this previous waste product.

Founded in the 1940s to supply desiccated coconut to a US-based maker of chocolate bars, the company’s integrated coconut processing plant near Manila, stands amongst sprawling coconut plantations. These plantations provide the raw materials for a wide variety of coconut products is produced, including coconut water.

The challenge for the company and other coconut processors has been how to profitably produce and transport the in-demand coconut water from remote corners of the Philippines, Indonesia, Brazil, Sri Lanka, India, Malaysia, and Thailand to reach the millions of eager consumers, thousands of kilometres away.

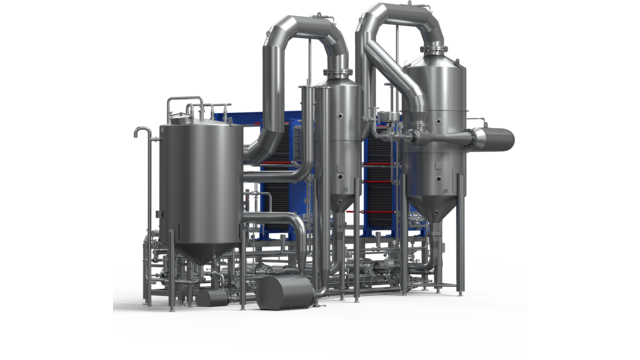

For the company in question, the solution has been the incorporation of Alfa Laval’s AlfaVap evaporation system into the line at its plant, which processes 300,000 coconuts a day. The resulting 90,000 litres of coconut water produced is reduced to 6,000 litres of concentrate, generating significant savings in packaging and transport costs, while also reducing the carbon footprint significantly. One of the early adopters of this processing method, they now wholly supply a major global beverage giant.

“The costs to pack and transport large volumes of coconut water are huge, so we suggested that the customer produce coconut water concentrate. This costs less to package and ship to destinations around the world where it is reconstituted, repackaged for retail and sold,” explains Dharmendra Shukla, Regional Market Unit Manager, Food Solution & Protein. “Normally, with concentrate, a lot of vitamins and nutrients are lost, but the AlfaVap technology is designed with minimal impact on the reconstituted product quality. It is low-temperature evaporation, with the final product coming out at 45-48°C once through technology, so the nutrient levels and the colour are minimally affected.”

By recovering 84,000 liters of water every day, the AlfaVap technology has also reduced the pressure on the plant’s wastewater treatment facility - the total volume of effluent is lower, and the condensate from the evaporator is clean and can potentially be used for cleaning applications or safely discharged with minimal treatment.

“Processing the coconut water has dramatically reduced the amount of water going to the wastewater treatment plant,” says Dharmendra. “The customer has cut their wastewater treatment costs and is also making money from a by-product that was previously wasted. It is a win-win from a sustainability perspective, and it is also profitable.”

Highlighted technologies

By reducing the volume of coconut water by 93%, carbon emissions as a result of the transportation of the finished product over thousands of kilometres is drastically reduced.

84,000 liters of water is recovered every day. Once adequately treated, the water can be released into local watersheds and will aid the replenishment of local water systems.