Alfa Laval Aalborg waste heat recovery boilers increase CCPP steam cycle output by 40%

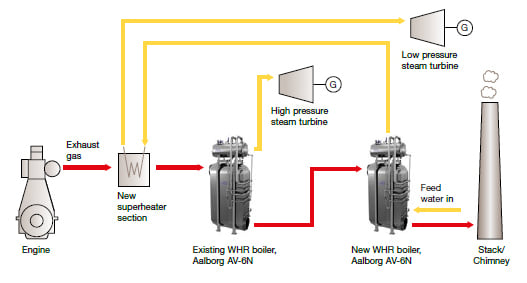

When converting from the use of heavy fuel oil to natural gas at its Samsun combined-cycle engine powerplant, Turkish power producer Cengiz Enerji Sanayi ve Ticarat AS increased the steam cycle output by 40% by adding new Alfa Laval Aalborg AV-6N exhaust gaswaste heat recovery (WHR) boilers and superheater units.

DATE 2566-11-28Located in Samsun on the northern coast of Turkey, this Cengiz Enerji plant was initially constructed with exhaust gas WHR boilers supplied by Alfa Laval Aalborg Oy (Rauma, Finland). These Aalborg WHR boilers captured the energy from the exhaust gas after combustion of heavy fuel oil in order to produce steam. Steam was then converted into mechanicalenergy by a high-pressure steam turbine, providing 8 MWel in total output.

40% increase in steam cycle output

Modification of engines in order to be able to burn natural gas instead of heavy fuel oil increased the amount of exhaust gas heat that was available for recovery. To take full advantage of the available waste heat, Alfa Laval Aalborg Oy supplied seven new WHR boilers downstream existing WHR boilers. The new WHR boilers generate superheated low pressure (LP) steam, which is used in a new LP steam turbine.

Alfa Laval Aalborg Oy designed separate superheaters upstream the existing WHR boilers thereby safeguarding the existing equipment from higher exhaust temperatures. By upgrading the plant with additional Aalborg AV-6N boilers, Cengiz Enerji boosted steam cycle output by 40% and further secured proper functionality of the original equipment too.

Cost-effective upgrade, reduced emissions

Due to limited space, Alfa Laval Aalborg Oy reused existing DeNOx casingframes to house the superheaters since, after the conversion to natural gas, controlling nitrogen oxide emissions was no longer necessary. Smart reuse of the casing frames made the plant upgrade fast and economical because less additional construction work was required.

Alfa Laval Aalborg Oy supplied seven new Aalborg AV-6N boilers and seven new superheaters, which increased output from the steam cycle of the Cengiz Enerji power plant by up to 40%.

About the Aalborg AV-6N

The Aalborg AV-6N, a water-tube waste heat recovery boiler is a robust, highly efficient boiler, designed to improve overall plant efficiency.

With the Aalborg AV-6N WHR boiler, waste heat from exhaust gas can be recovered from various sources, such as industrial processes and diesel or gas engines to generate steam and/or hot water. With its flexible design, it is easy to install – even in existing facilities.

Fast facts

About the customer

Turkish power producer Cengiz Enerji is an independent subsidiary of the Cengiz Holding Group. Together with its partners, Cengiz Enerji is responsible for distributing 30% of the total electricity consumption in the five regions in which it operates in Turkey.

The challenge

To ensure smooth conversion from heavy fuel oil to natural gas, optimize utilization of excess exhaust gas heat despite limited space, safe guard plant reliability and reduce emissions.

The solution

Seven specially designed Alfa Laval Aalborg superheater units (installed in former DeNOx casings) downstream the existing 17MWe engines, in combination with seven new Alfa Laval Aalborg WHR AV-6N boilers.

The benefits

An increase of approximately 40% in electricity output from the steam cycle and safeguarding original CCPP equipment.

Start up

2003 and 2013