Foodec

Alfa Laval Foodec decanter centrifuges are ideal for industries where delicate food and beverage products are processed – and where easy cleaning is crucial.

Centrifugal separator with unparalleled efficiency and easy cleaning

- Higher juice extraction yield, drier cake and clearer liquid

- Easy and fast cleaning with CIP thanks to AL cleaning technology and software

- High operational flexibility to adapt to different processes or fruits

- Wide range of available decanter size all with premium G-Force level

Brewery

Alfa Laval has a proven track record for supplying advanced-technology industrial food processing machinery and equipment to meet brewing industry requirements - with prime focus on the separation processes involved.

Fruit juice

For all fruit juice producers, efficient juice extraction and maximum yield at minimum cost is crucial. You also have to observe stringent hygiene standards. Foodec decanter centrifuges have the versatility and hygiene focus to enable you to achieve all this.

Milk

Alfa Laval Foodec decanter centrifuges provide you with an efficient, profitable way of processing casein and lactose into attractive, high-value dairy products.

Soy protein

The unique design of the Alfa Laval Foodec decanter centrifuges features a series of built in advantages that provide you with substantial processing benefits. The most hygienic and efficient way to process soy protein isolate.

Plant-based beverages such as oat, almond and rice drinks

Foodec is ideal for plant-based drink production with focus on reliability, optimization of water and energy consumption and getting the most out of your raw material, from soy and oat to almonds, rice and beyond.

Tomato

Tomatoes are used in huge numbers of food products. This also means that there are many different types of tomato processing involved. Foodec decanter centrifuges are one of the few types of equipment with the versatility and hygiene focus to be able to handle this.

Wine

Foodec decanter for grape juice processing and winemaking. The high efficiency of decanter centrifuges for food processing makes it possible to replace traditional presses and clarification equipment in winemaking.

How it works

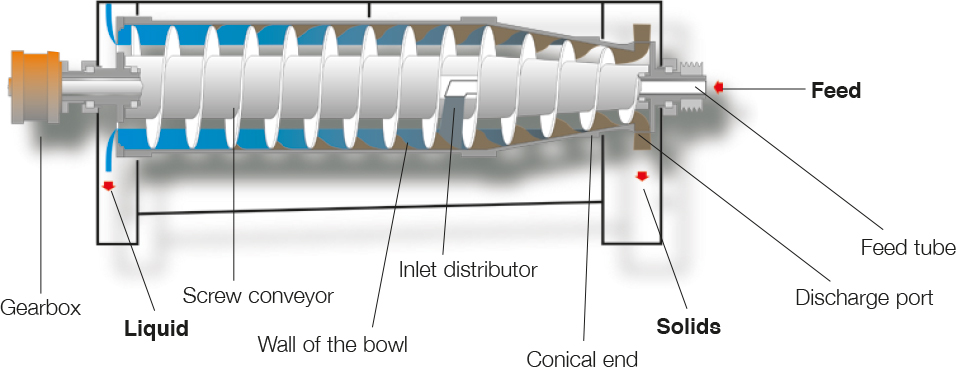

How does the Foodec decanter centrifuge work

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. A stationary inlet tube introduces the product into the bowl, and a distributor gradually accelerates it. Centrifugal forces separate solids from the liquid. The solids are collected and compacted on the bowl wall.

A conveyor rotates inside the bowl at a slightly different speed. This transports the settled solids on the bowl wall towards the conical end. Foodec's design increases hydraulic pressure inside the drum to improve flow through a narrow opening. The compacted and dewatered solids leave the bowl via discharge openings at the smaller diameter of the conical end. Separation takes place in the entire length of the cylindrical part of the bowl, and the clarified liquid leaves through a paring disc (internal centripetal pump).

All wetted parts in Foodec decanter centrifuges for the food industry are made with stainless steel. The control system is equipped with a graphic user interface and multiple communication options.

Upgrade your Foodec with SaniRibs® transportation aid

Intended for separation tasks in the food industry, the SaniRibs design eliminates crevices under traditional spot-welded transportation aids and minimizes the risk of bacterial growth, offering a unique combination of excellent hygiene and outstanding separation performance

Maximize operating reliability with Alfa Laval IoT Services

Alfa Laval’s IoT Services is a range of digital services that maximizes operating reliability and uptime in food & beverage processing plants.