Precious Minerals and Mining

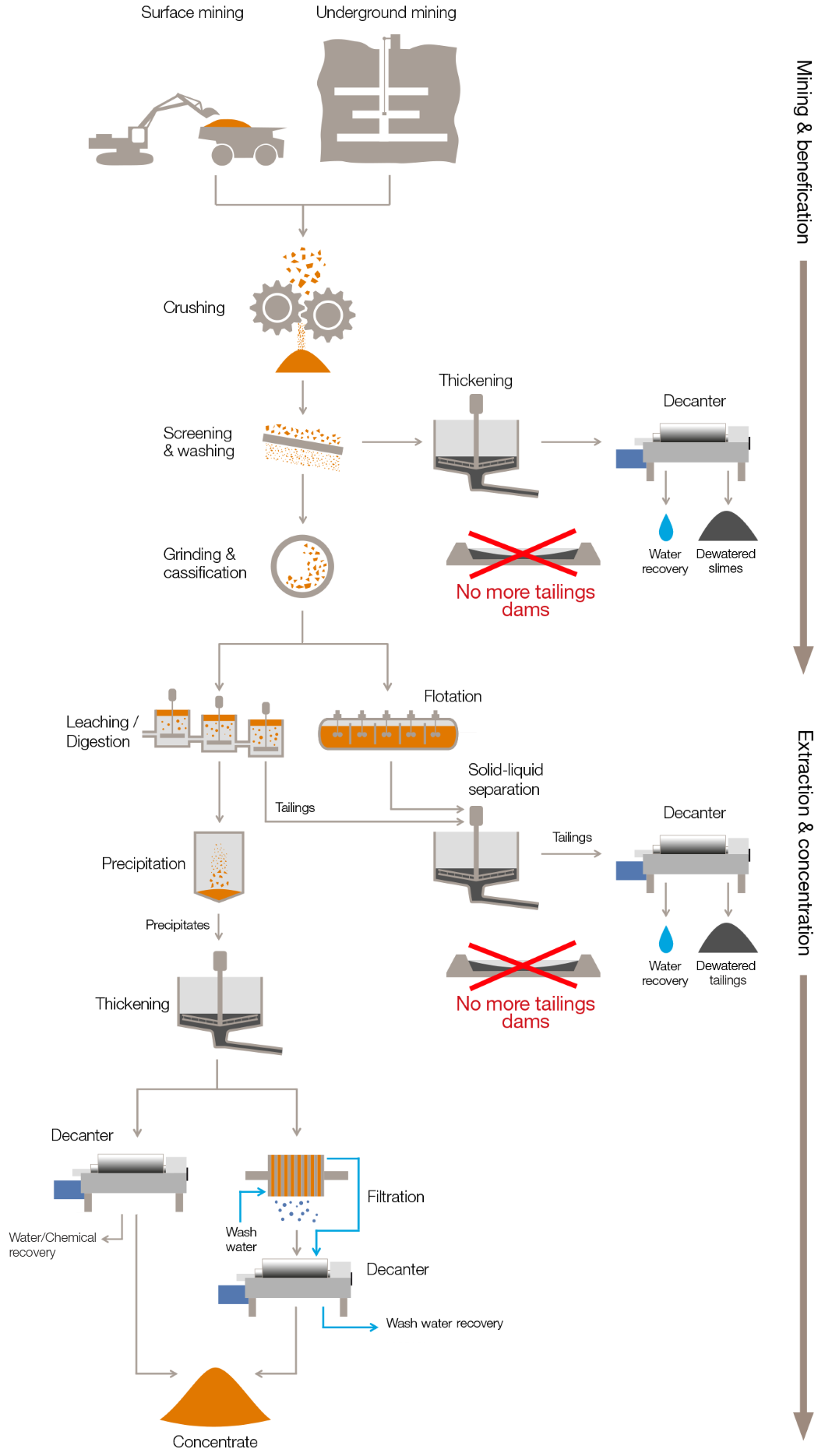

Alfa Laval has a range of equipment to optimize key processes such as separation and heating and cooling in the beneficiation, leaching and extraction of precious mineral ores including gold, platinum and silver. Our solid-liquid separation can be used in various process steps including dewatering of ore concentrates. Importantly, this technology is a proven alternative to manage tailings safely and cost effectively without the use of dams.

Robust technology designed for tough mining applications

- Optimal operation performance with minimal intervention

- High volume capacities with smaller foot-prints save space

- Contained processes resulting in clean and safe working conditions

- Maximize recovery of valuable products, water and waste heat

- Water re-use helps boost operational sustainability

Tackling tailings safely and sustainably

Alfa Laval decanter centrifuges are a proven, efficient solution for large-scale dewatering of tailings and removing the finest particles that conventional solids control equipment is unable to deal with. They offer a cost effective, sustainable and, above all, safe solution to manage tailings, acting as a complement to traditional separation systems such as thickeners, sedimentation basins and filters or replacing old systems altogether.

มุ่งมั่นเพื่อมาตรฐานใหม่

ขอแนะนำเครื่องแลกเปลี่ยนความร้อนแบบแผ่นที่ทันสมัยที่สุดในโลก ค้นพบว่าเครื่องแลกเปลี่ยนความร้อนแบบแผ่นที่ใช้ปะเก็นรุ่นใหม่ของเรามีประสิทธิภาพที่ดีกว่า มีความทนทานที่สูงกว่า และซ่อมบำรุงได้ง่ายกว่าได้อย่างไร

โอกาสที่เป็นไปได้ในกระบวนการของคุณทั้งหมด

สำรวจผังงานการทำเหมืองแร่และค้นหาว่าเครื่องปั่นเหวี่ยงดีแคนเตอร์ Alfa Laval สามารถช่วยทำให้การดำเนินงานของคุณในกระบวนการด้านต่างๆ ให้ทันสมัยขึ้นได้อย่างไร

On the pulse of precious minerals and mining processing

Alfa Laval help producers of gold, silver and platinum to get the most out of raw ores – cost-effectively, energy-efficiently and in an environmentally friendly way. From smart reuse of process waters and recirculation of cooling waters to treatment of bleed streams and smart solid waste reduction, count on Alfa Laval. Smart reuse of the vast amounts of heat involved in these processes can contribute directly to the bottom line. While dewatering and separation technologies help extract valuable by-products, reduce waste streams, and minimize environmental impact. Alfa Laval has the process know-how as well as a broad portfolio of equipment and services to help precious mineral and mining producers cut costs, achieve significant energy savings and raise yields.

Big energy savings through heat transfer

Beneficiation, digestion, roasting, leaching, smelting and electro-winning are all energy-intensive processes. By harnessing the heat generated during extraction processes and reusing it in other processes, metal producers not only save big on energy costs, but also boost productivity.

Our heat exchangers (gasketed, welded or spiral) are a proven and highly efficient technology for heat transfer to feed the heat back into the process with unparalleled yield. The heat exchangers’ close temperature approach, high internal turbulence and large heat-transfer areas combine to squeeze out up to 30% more energy than conventional shell-and-tube units out of every heat flow. By replacing costly and bulky units with Alfa Laval heat exchangers, processing plants can save cost and many megawatts of hidden energy each year.

Optimizing separation efficiency

Whether used for solvent extraction, electrowinning, dewatering, recovery of intermediate products, or separation processes, Alfa Laval decanter and separators are reliable, resilient and equipped to deal with the complex solid-liquid or solid-liquid-liquid separation processes involved in mining production production.

Due to highly efficient operation, robust design and the resulting high purity output, Alfa Laval separation solutions are an integral part of nearly all processes in the recovery of mineral raw materials. Which is why metal producers the world over rely on Alfa Laval to help maximize productivity and increase yields.

Customer stories

Alfa Laval decanters revolutionize coal mine tailings management strategy

The Rix’s Creek coal mining operation, part of the Bloomfield Group, set out to improve its onsite coal tailings management as part of its sustainability strategy to reduce water and energy consumption and minimize the surface footprint of waste handling processes.

Alfa Laval Compabloc condenser solved fouling problem

Queensland Alumina replaced a shell-and-tube unit with a fully welded Alfa Laval Compabloc condenser unit in order to decrease maintenance costs. Utilising only a quarter of the space of the old shell-and-tube installation, the Compabloc solved severe corrosion and fouling problems resulting in a significant service cost reduction.

Kaolin production in the Amazon jungle

The extremely remote location of its raw material source does not prevent Cadam in Brazil from developing its kaolin production into an increasingly successful business.

Energy savings for cooling copper smelters

Rönnskär copper smelter signed a three-year Performance Agreement with Alfa Laval resulting in saved plate heat exchanger energy costs, reduced water consumption and increased uptime.

การจัดการแยกหางแร่

พบกับความท้าทายในการบำบัดน้ำทิ้งหางแร่ด้วยเครื่องปั่นเหวี่ยงดีแคนเตอร์ของ Alfa Laval ถือเป็นเสนอโซลูชันที่คุ้มค่า ยั่งยืน และเหนือสิ่งอื่นใด คือปลอดภัยในการจัดการแยกหางแร่ ดาวน์โหลดโบรชัวร์เพื่ออ่านเพิ่มเติมเกี่ยวกับระบบแยกของแข็งและของเหลวของเราที่สะอาดกว่า มีประสิทธิภาพสูงกว่า และปลอดภัยมากกว่า

Learn more

Read more about the efficiency, practicality and technical details of our range of equipment for solid-liquid separation in precious mineral ore processing by downloading the brochure

Tough and efficient, tried and tested

If you are looking for safe, sustainable and cost-effective technologies in precious mineral ore processing, contact Alfa Laval today to learn more about our robust and well-designed solutions.