Why Alfa Laval

With more than 80 years of experience in heat transfer innovation, Alfa Laval knows what it takes to deliver high-performance solutions for any application. Our experts continuously strive to find new ways of making your equipment more reliable, more efficient, and simpler to operate and maintain. That’s why you can depend on solutions that are ready for today’s challenges as well as the demands of tomorrow.

But the equipment is just the beginning. When you choose Alfa Laval, you are choosing a committed partner who will be available to you every step of the way. Thanks to our global support network, we can assist with any technical challenge, anywhere in the world. From sales to delivery, commissioning to service and spare parts, the expertise and support that you need is always at your fingertips.

Brazed and fusion-bonded plate heat exchangers

Everything you need to meet your challenges today – and tomorrow

These are some of the many unique benefits you can expect when you choose to partner with Alfa Laval.

PressureSecure

PressureSecure

Unparalleled strength for demanding duties

Our innovative plate designs support the widest range of high-temperature and high-pressure applications. Units can run using thinner plates and fewer plates, which translates to less raw material, lower energy consumption, reduced refrigerant charge and a longer equipment lifecycle.

ValuePlus

ValuePlus

Total support – with value-adding options to fit your needs

Get access to a wide range of tools as well as Alfa Laval’s application and product experts. ValuePlus support includes all documentation, approvals and certifications in addition to an ever-expanding range of accessories. Thanks to Alfa Laval’s prototyping and testing expertise as well as our large-scale manufacturing capabilities, you can always expect fast delivery, and full compliance with any regulations.

REFuture

REFuture

A future-proof investment for tomorrow’s refrigerants

As an innovative driver in the development of solutions for natural refrigerants, Alfa Laval brings years of experience working with products that enable the use of new-generation and low-GWP refrigerants to help you meet sustainability goals and any legislative requirements.

FlexFlow™

FlexFlow™

Superior thermal performance

Alfa Laval’s patented asymmetrical plate design is one of many unique innovations that gives you improved thermal efficiency thanks to optimized pressure drop and increased turbulence. In addition to cutting energy consumption, that means reducing refrigerant volumes and raw materials.

DynaStatic™

DynaStatic™

Flexible refrigerant distribution

This breakthrough production method lets you fully tailor the placement, size and number of inlets to fit your specific application, ensuring the optimal refrigerant distribution system for your products. The result is higher efficiency with the flexibility to use low-GWP refrigerants.

AlfaNova®

AlfaNova®

100% stainless steel

Built with 100% stainless steel, AlfaNova® is a solution that Alfa Laval offers for applications that use media not compatible with traditional heat exchanger materials. Not only is this advanced design optimized for use with natural refrigerants, it’s also completely recyclable.

IceSafe

IceSafe

Controlled, non-destructive freezing

For applications that require it, we can supply plate heat exchangers designed to allow ice crystals to form under certain operating conditions, but displaced from sensitive areas. This ensures both reliable performance and a long product life.

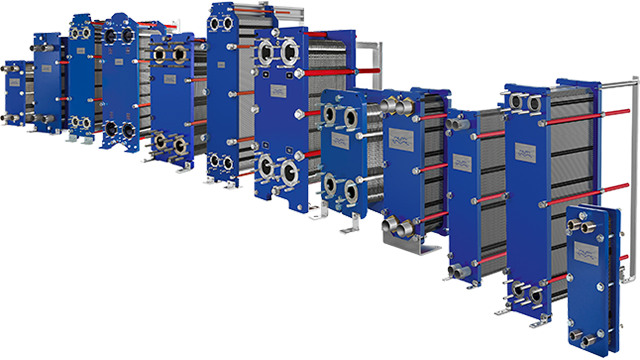

Gasketed plate and frame heat exchangers

Groundbreaking heating and cooling innovations

Years of research and testing have resulted in the world’s most modern plate heat exchangers for heating and cooling applications. Packed full of features unique to Alfa Laval, these designs provide improved efficiency, reliability and serviceability.

CurveFlow™

CurveFlow™

Improved flow, minimized fouling

The CurveFlow™ distribution area optimizes the flow of media for better utilization of the whole plate surface. Improving the flow with more even distribution eliminates dead spots, providing higher thermal efficiency with reduced risk of fouling. This in turn means energy savings, lower maintenance costs and less time worrying about unplanned stops.

ClipGrip™

ClipGrip™

Perfect seal and trouble-free maintenance

ClipGrip™ gaskets offers superior fastening to the plate, with gaskets that are also easier to mount. The unique design prevents snaking of plates at closing and the tangling of new gasket sets. Maintenance goes faster, plates and gaskets last longer, and you save money as a result.

Five-point alignment

Five-point alignment

Perfect positioning for total reliability

This system ensures perfect plate alignment when closing the unit, while simultaneously making it quick and easy to remove plates during maintenance. Excellent plate positioning secures reliable mechanical performance and helps extend the life of your equipment.

OmegaPort™

OmegaPort™

Enhanced thermal efficiency

Alfa Laval’s noncircular inlet and outlet offers two ways to save on energy: both higher thermal efficiency and reduced pump costs. That’s because it enhances the flow of media to give increased throughput, lower pressure drop and optimal utilization of the plate surface.

Offset gasket grooves

Offset gasket grooves

Maximum heat transfer

A gasket groove in a special zigzag pattern offers the greatest possible heat transfer area. Better utilization of the whole plate reduces the number of plates required for optimal performance and ensures maximum thermal efficiency for still greater energy savings.

T-bar roller

T-bar roller

Lower height and easier service

A patented carrying bar design protects the roller from falling dust and debris, preventing jamming and minimizing the potential for damage to the frame. It further ensures lower unit height and easier opening and closing for service.

PowerArc™

PowerArc™

The longest possible plate lifetime

Our optimized plate pattern divider ensures a more rigid plate, preventing plate elongation and securing perfect alignment. The result is a more robust and durable plate, which further provides more efficient heat transfer.

Bearing Boxes

Bearing Boxes

Smoother, safer, simpler maintenance

Many of our large and medium plate heat exchangers employ tightening bolts with bearing boxes to reduce friction when opening and closing the unit. This makes it possible for one person to easily and safely service the heat exchanger without the need for special tools.

Industrial semi-welded line

Total reliability and efficient thermal performance

Semi-welded plate heat exchangers are suitable for refrigeration, chemical processes and various kinds of industrial utility duties. The unique Alfa Laval RefTight™ sealing system guarantees a long lifetime sealing between the welded channels because the laser weld is on the outside of the ring gasket groove. The smooth surface ensures a tight uniform seal over the entire gasket ring.

CurveFlow™

CurveFlow™

Improved flow, minimized fouling

The CurveFlow™ distribution area optimizes the flow of media for better utilization of the whole plate surface. Improving the flow with more even distribution eliminates dead spots, providing higher thermal efficiency with reduced risk of fouling. This in turn means energy savings, lower maintenance costs and less time worrying about unplanned stops.

RefTight™

RefTight™

High-performance gasket sealing for high-pressure duties

The RefTight™ sealing system enables enhanced, long-term performance in applications with high pressures and temperatures. The weld is positioned outside the separate ring gasket groove, ensuring reliable sealing as well as extended gasket lifetime and prolonged service intervals.

OmegaPort™

OmegaPort™

Enhanced thermal efficiency

Alfa Laval’s noncircular inlet and outlet offers two ways to save on energy: both higher thermal efficiency and reduced pump costs. That’s because it enhances the flow of media to give increased throughput, lower pressure drop and optimal utilization of the plate surface.

Five-point alignment

Five-point alignment

Perfect positioning for total reliability

This system ensures perfect plate alignment when closing the unit, while simultaneously making it quick and easy to remove plates during maintenance. Excellent plate positioning secures reliable mechanical performance and helps extend the life of your equipment.

Compact frame

Compact frame

Facilitates maintenance and minimizes service area requirement

The Compact frame feature offers more capacity in a smaller footprint. The smart guiding bar enables a maximum number of plates or cassettes in the frame while keeping the service area requirements down to a minimum. The design enables a faster and safer service which minimizes downtime and reduces maintenance costs.

Bearing Boxes

Bearing Boxes

Smoother, safer, simpler maintenance

Many of our large and medium plate heat exchangers employ tightening bolts with bearing boxes to reduce friction when opening and closing the unit. This makes it possible for one person to easily and safely service the heat exchanger without the need for special tools.

T-bar roller

T-bar roller

Lower height and easier service

A patented carrying bar design protects the roller from falling dust and debris, preventing jamming and minimizing the potential for damage to the frame. It further ensures lower unit height and easier opening and closing for service.

ClipGrip™

ClipGrip™

Perfect seal and trouble-free maintenance

ClipGrip™ gaskets offers superior fastening to the plate, with gaskets that are also easier to mount. The unique design prevents snaking of plates at closing and the tangling of new gasket sets. Maintenance goes faster, plates and gaskets last longer, and you save money as a result.

IceSafe

IceSafe

Controlled, non-destructive freezing

For applications that require it, we can supply plate heat exchangers designed to allow ice crystals to form under certain operating conditions, but displaced from sensitive areas. This ensures both reliable performance and a long product life.

Quick selection guide

The Alfa Laval product guide is an easy-to-use tool to help you select the best solution for your application. It also lists local Alfa Laval partners and you can request a quotation for your selected product.

ศูนย์กลางระบบทำความร้อนและความเย็นใหม่ล่าสุดสำหรับคุณ

ด้วยความเชี่ยวชาญจากประสบการณ์ด้านเครื่องแลกเปลี่ยนความร้อนเป็นเวลาหลายทศวรรษ Alfa Laval พร้อมให้ข้อมูลความรู้เพื่อตอบโจทย์ความท้าทายด้านระบบทำความร้อนและความเย็นในปัจจุบัน ค้นพบคำตอบของคำถามที่ซับซ้อนทุกข้อตั้งแต่ประสิทธิภาพการใช้พลังงานไปจนถึงสารทำความเย็นจากธรรมชาติ พร้อมด้วยเครื่องมือช่วยเหลือที่ทำให้การค้นหาเทคโนโลยีที่เหมาะสมสำหรับการใช้งานของคุณทำได้ง่ายขึ้น