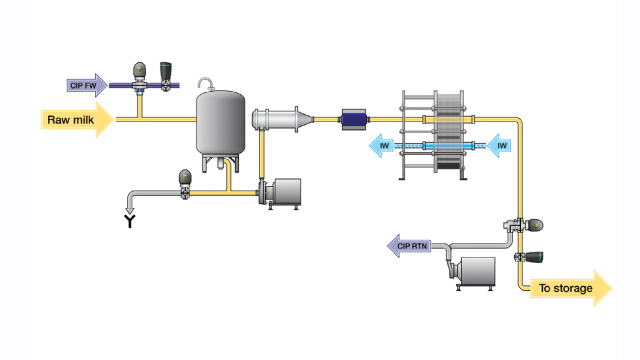

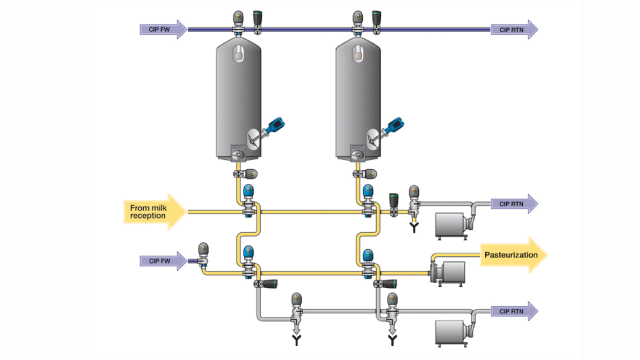

Milk reception

Milk reception and storage demand uptime and efficiency. That means components with high reliability, easy serviceability, and both operational and energy efficiency.

Highlighted Alfa Laval Innovative Equipment

Alfa Laval Tubes and Fittings

• Problem free welding and assembly

• Optimized internal design and robust construction

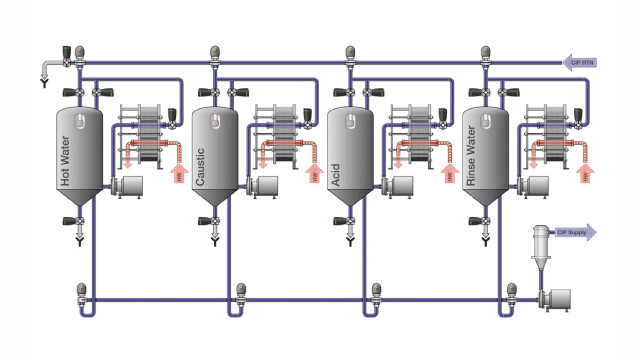

• Suitable for Cleaning-in-Place and EHEDG certified

Alfa Laval BaseLine Heat Exchanger

• More uptime and lower maintenance costs

• Low spare part usage and costs

• No bacteria growth saves time and cuts Cleaning-in-Place costs

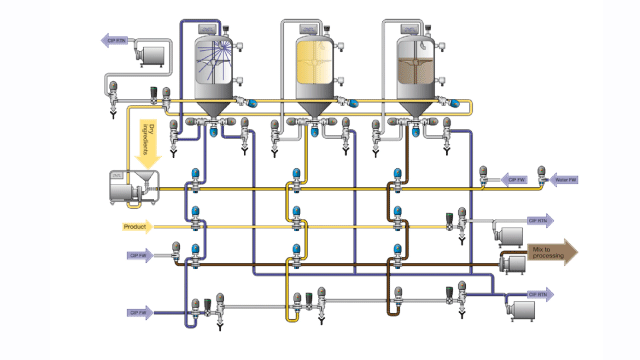

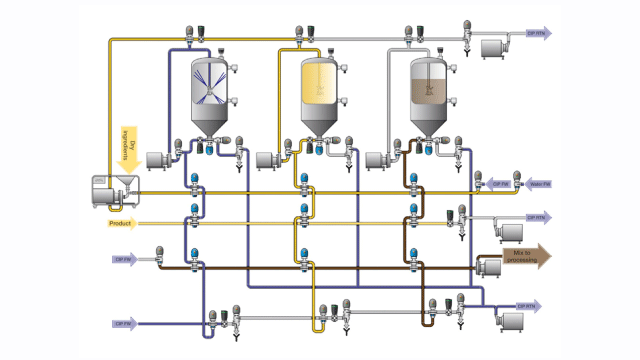

Optimizing Dairy Processes

Energy Savings

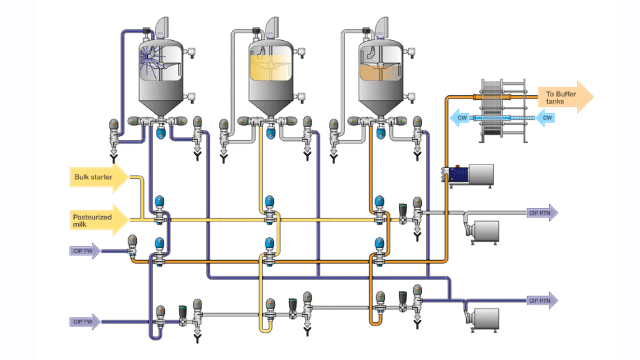

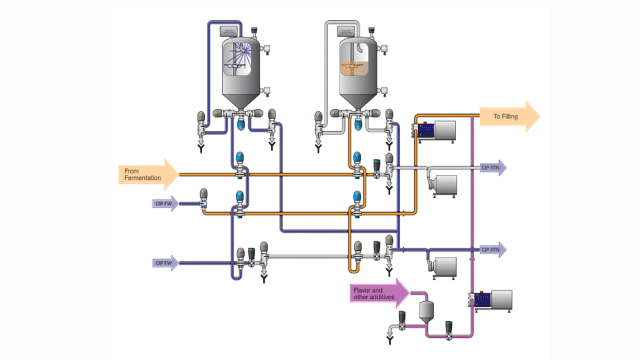

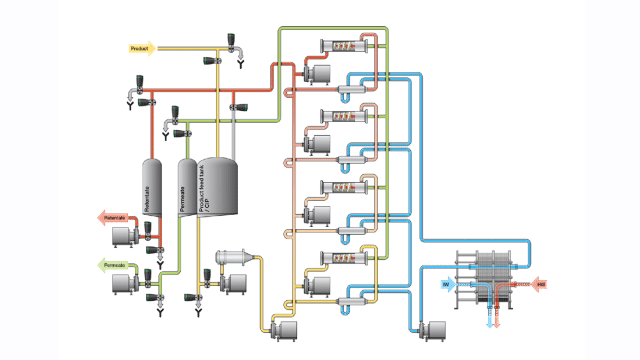

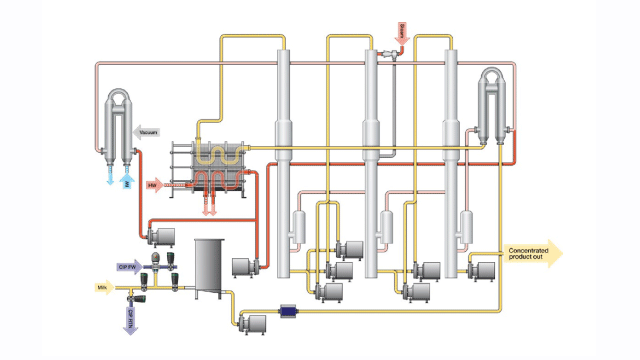

HATSUN PRIVATE DAIRY LTD, INDIA. Alfa Laval was the sole supplier for this dairy’s new curd plant, which produces 40 kilolitres of curd per day.

The scope of delivery was comprehensive. Alfa Laval contributed expertise as well as supplying high-quality equipment such as agitators, valves, centrifugal pumps, plate heat exchangers, tank cleaning machines, and fittings, with the backing of a service and support agreement.

As a result, the dairy has increased energy efficiency, hygiene, and uptime at its plants.