India's biggest paper mills chose AlfaCond from Alfa Laval

When Sirpur Paper Mill decided to invest in a brand-new evaporation plant for processing and reusing the mill waste known as “black liquor,” Executive Director SK Khare knew exactly where to turn. He had worked successfully on many projects with Alfa Laval during his 25 years in the paper business. And this latest project has proven just as successful.

DATE 2568-12-12Always on the lookout for improvement

Incorporated in 1938, The Sirpur Paper Mills Limited is one of the largest manufacturers of paper and paperboard in India. Sirpur Paper Mill has been investing heavily to bring its facilities in line with international standards and increase capacity.

“We’re constantly hunting for proven technology at the right price to help us save energy, reduce steam-consumption costs and improve process efficiency. When we decided to invest in the new falling film evaporation plant for handling black liquor, we had detailed discussions with Alfa Laval’s technical team.”

- Mr. Khare.

After extensive evaluation, the Sirpur technical team selected Alfa Laval’s evaporation plant, with AlfaCond as the condenser in the black liquor evaporation plant.

For paper mills, effectively handling the waste product “black liquor” goes a long way towards solving the environmental issues associated with it.

For paper mills, effectively handling the waste product “black liquor” goes a long way towards solving the environmental issues associated with it.

The difference is obvious

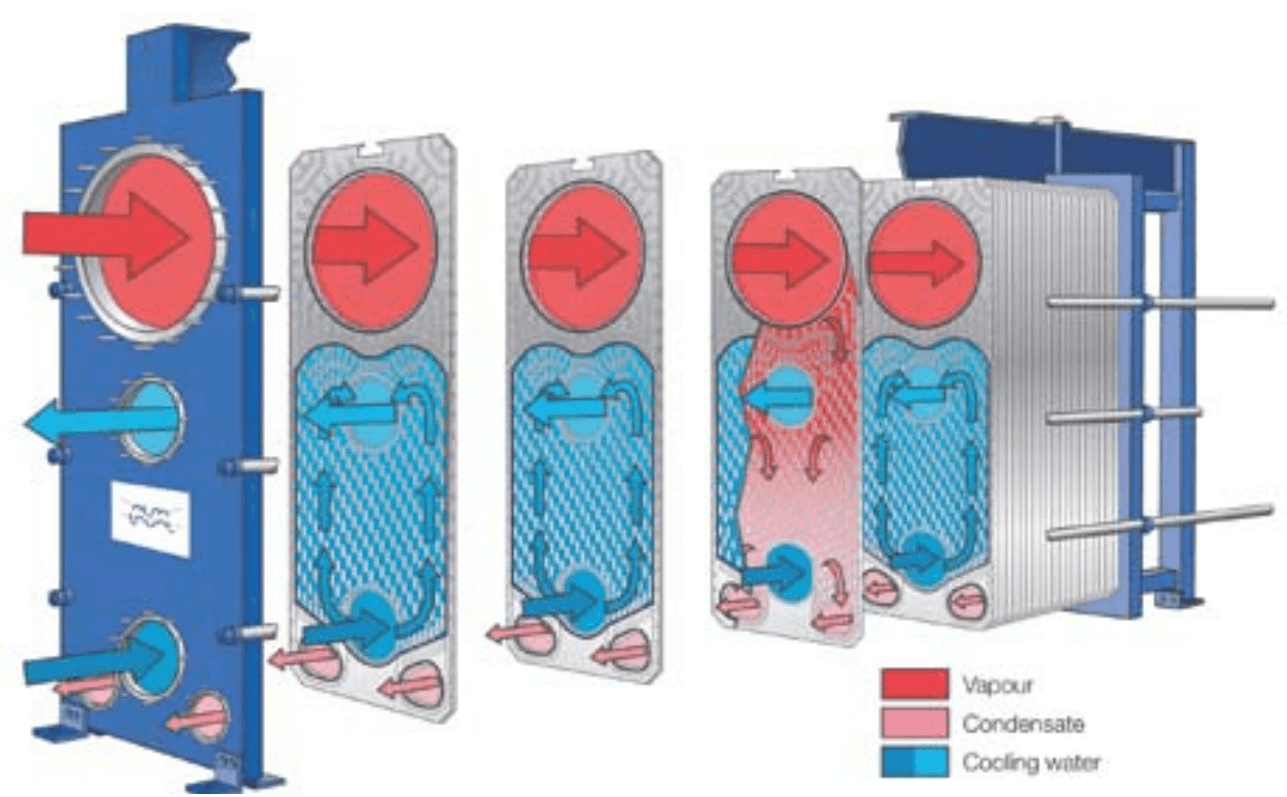

The complete solution includes both shell-and-tube heat exchangers and AlfaCond, working side-by-side. And the difference is obvious.

AlfaCond is a highly efficient and extremely compact alternative to bulky conventional shell-and-tube units. It costs much less to install and requires only one-third the space. Plus, maintenance time can be measured in hours, rather than days.

The final results? Better volume, cleanliness and profitability

At the Sirpur Paper Mill, the AlfaCond condenser operates in the last stage of the black liquor evaporation system, separating out non-condensable gases along with highly contaminated vapors from the 5th 6th and 7th effects. It allows Sirpur to separate out highly contaminated condensate for disposal. So the quality of the remaining condensate is better now, and it can be used as hot process water in Sirpur’s caustisizing plant.

Furthermore, since the evaporator has been up and running, evaporation improved from 3.5 tons per ton of steam to 6.5 tons per ton of steam and also resulted in a higher liquor concentration. This, in turn, improved steam generation in the soda recovery boilers.

That’s how much I trust them

Executive Director Khare has known Alfa Laval for more than 25 years. According to him, Alfa Laval technologies are proven globally, which is why when the Sirpur Paper Mill planned for expansion, they confidently accepted the recommendations of the Alfa Laval technical team. Mr Khare describes the relationship between his company and Alfa Laval like this:

We ‘blindly’ followed the recommendations of the Alfa Laval team. That’s how much I trust them.”And so far, Alfa Laval – and the AlfaCond – have proven themselves worthy of that trust: For one thing, the evaporation system was commissioned on time, which is a good way to begin a relationship. And while it’s too soon for Sirpur to calculate the exact savings to the company, they say that the new plant is definitely giving them an advantage in handling the black liquor effectively, something that goes a long way towards solving the environmental issues associated with black liquor disposal.

We surely would partner with Alfa Laval in future expansion plans”

- Mr. Khare

Product

Condensing plays an important part in process industries of virtually all kinds, including (energy), chemicals and food.

Benefits

- Evaporation increased from 3.5 tons per ton of steam to 6.5 tons per ton of steam

- Improved quality of remaining condensate

- Lower installation costs

- Less space needed for installation

- Less maintenance

Challenge and solution

The company wanted to increase capacity, save energy and get the best possible quality and steam economy out of their investment in a new falling film evaporation plant for handling black liquor.

The complete solution at Sirpur Paper Mills includes both shell-and-tube heat exchangers and AlfaCond, working side-by-side for a highly efficient and extremely compact alternative to bulky conventional shell-and-tube units alone.